Get In Touch

- 5201 Blue Lagoon DR suite 972 FL Miami 33126

- [email protected]

- [email protected]

- +1 (561) 4505077

- +1 (561) 888 1922

INQUIRE NOW

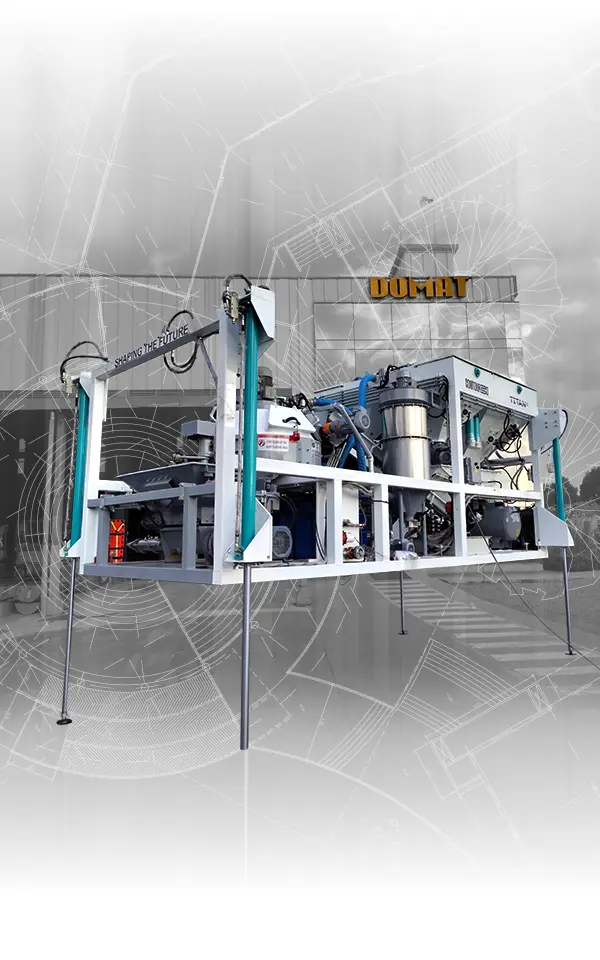

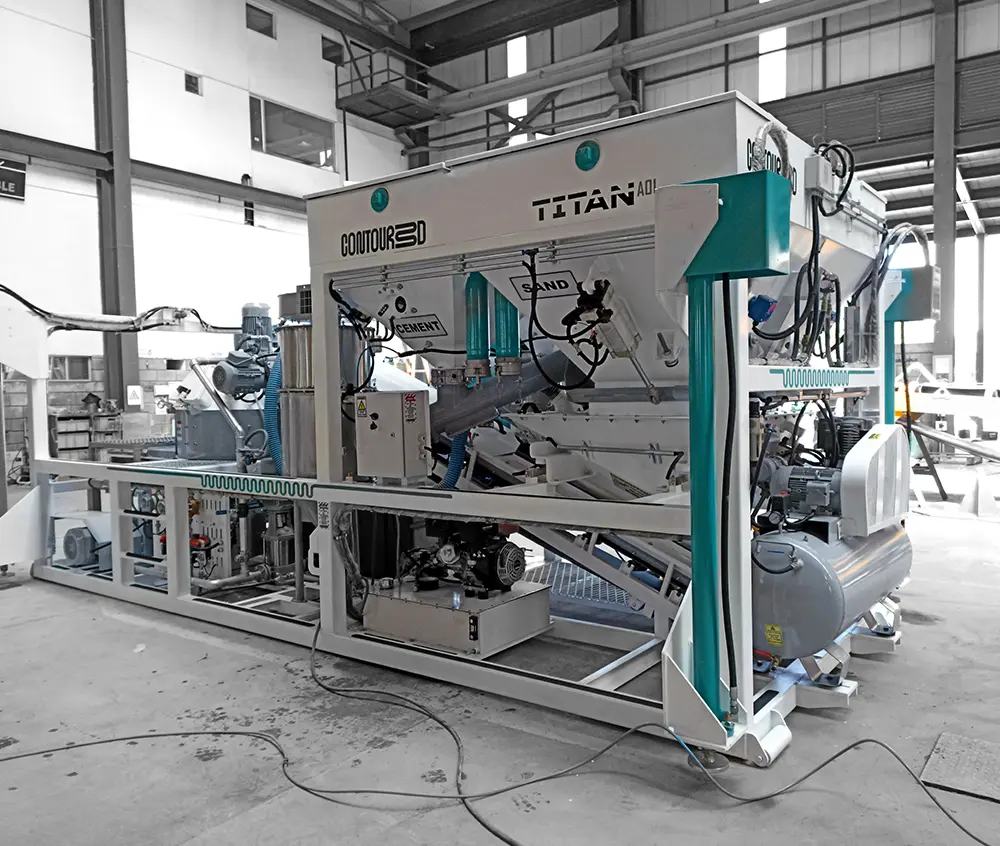

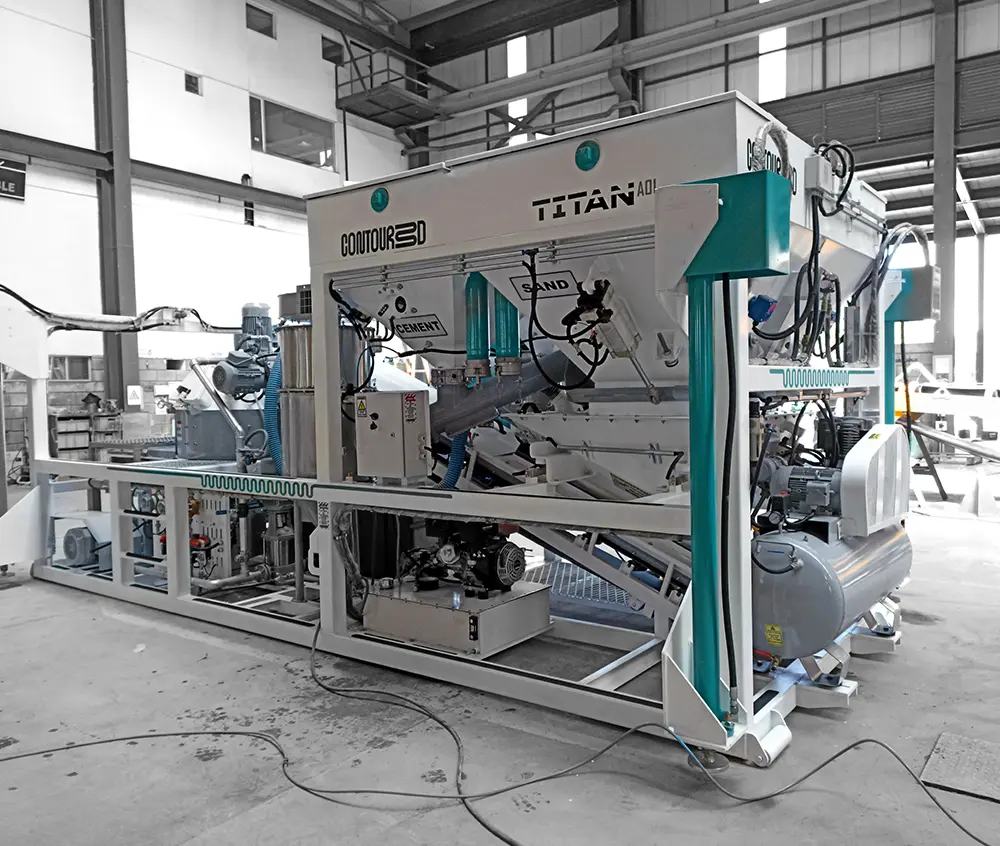

DMI Series 3D

The DMI Series from Domat is specifically designed for the storage, transport, dosing, and precise mixing of aggregates, cement, and additives necessary for producing high-performance concrete and mortar. These plants are ideal for feeding 3D concrete printers, whether using a robotic arm or gantry systems.

Thanks to their automatic gravimetric dosing systems, they guarantee exceptional accuracy and production continuity. Equipped with DOMAT’s advanced planetary mixers, featuring a dual-action vertical shaft (rotation and translation), the DMI Series ensures highly efficient homogenization of special and high-specification concrete mixes. Optional features include moisture sensors (Hydro-mix), temperature sensors, and an automatic high-pressure wash system, making the DMI Series the perfect choice for 3D printing applications in the construction sector.

DMC series specifications

|

Production (Lb/h): |

(0.653975) |

|

Mixer Type: |

Planetary Vertical Axis |

|

Porduction (lb/h)??? |

(0.130795) |

|

Aggregate hoppers capacity (yd³): |

Set according to need |

|

Control and dosing software: |

D200 |

|

Operation cabin |

Yes |

|

Shipping options |

Container 20’ |

|

Production (Lb/h): |

(1.30795) |

|

Mixer Type: |

Planetary Vertical Axis |

|

Porduction (lb/h)??? |

(0.26159) |

|

Aggregate hoppers capacity (yd³): |

Set according to need |

|

Control and dosing software: |

D200 |

|

Operation cabin |

Yes |

|

Shipping options |

Container 20’ |

Production (Lb/h): | (0.653975) |

Mixer Type: | Planetary Vertical Axis |

Porduction (lb/h)??? | (0.130795) |

Agregat hoppers capacity (yd³): | Set according to need |

Control and dosing software: | D200 |

Operation cabin | Yes |

Shipping options | Container 20’ |

Production (Lb/h): | (1.30795) |

Mixer Type: | Planetary Vertical Axis |

Porduction (lb/h)??? | (0.26159) |

Agregat hoppers capacity (yd³): | Set according to need |

Control and dosing software: | D200 |

Operation cabin | Yes |

Shipping options | Container 20’ |