Get In Touch

- 5201 Blue Lagoon DR suite 972 FL Miami 33126

- [email protected]

- [email protected]

- +1 (561) 4505077

- +1 (561) 888 1922

INQUIRE NOW

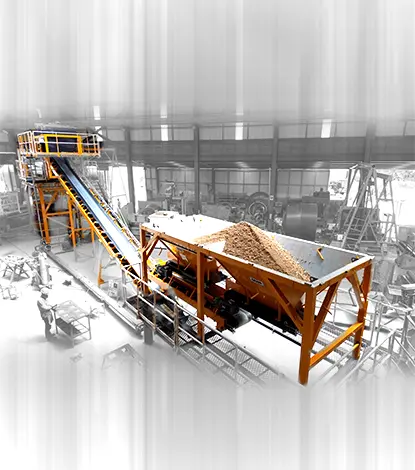

DMC Series

The DMC Series from Domat features industrialized plants specialized in the dosing and mass mixing of aggregates and cementitious materials, ideal for producing seating floors and soil base stabilization.

With configurable material options, these plants are equipped with DOMAT continuous mixers that ensure efficient homogenization and material transport.

Independent gravimetric weighing systems for aggregates and cement, along with water dosing controlled by flowmeters and automated software, guarantee precision and traceability throughout the process. The DMC Series is perfect for producing mixed concrete, compacted concrete (HCR, CCR), soil-cement mixtures, and mining sector backfill solutions.

DMC series specifications

Production (Lb/h): | (396832/440925) |

Mixer Type: | Continued double axis |

RMP Mixing shafts: | 85 |

Mixing paddles: | 44+4 |

Floor, wall and pallet coverings: | Replacement |

Type of motor: | Three-phase electric |

Engine power (Hp): | 30 |

Production (Lb/h): | (793664/881849) |

Mixer Type: | Continued double axis |

RMP Mixing shafts: | 68 |

Mixing paddles: | 40+8 |

Floor, wall and pallet coverings: | Replacement |

Type of motor: | Three-phase electric |

Engine power (Hp): | 2*30 |

Production (Lb/h): | (1190496/1322773) |

Mixer Type: | Continued double axis |

RMP Mixing shafts: | 50 |

Mixing paddles: | 40+8 |

Floor, wall and pallet coverings: | Replacement |

Type of motor: | Three-phase electric |

Engine power (Hp): | 2*40 |

Production (Lb/h): | (396832/440925) |

Mixer Type: | Continued double axis |

RMP Mixing shafts: | 85 |

Mixing paddles: | 44+4 |

Floor, wall and pallet coverings: | Replacement |

Type of motor: | Three-phase electric |

Engine power (Hp): | 30 |

Production (Lb/h): | (793664/881849) |

Mixer Type: | Continued double axis |

RMP Mixing shafts: | 68 |

Mixing paddles: | 40+8 |

Floor, wall and pallet coverings: | Replacement |

Type of motor: | Three-phase electric |

Engine power (Hp): | 2*30 |

Production (Lb/h): | (1190496/1322773) |

Mixer Type: | Continued double axis |

RMP Mixing shafts: | 50 |

Mixing paddles: | 40+8 |

Floor, wall and pallet coverings: | Replacement |

Type of motor: | Three-phase electric |

Engine power (Hp): | 2*40 |

DMB Series

Industrialized plants specialized in the batching and massive mixing of materials by batches, with the ability to configure the required number of aggregates, additives, and cementing agents in the mix. Equipped with DOMAT TWIN-SHAFT mixers for highly efficient material homogenization, these plants feature independent gravimetric weighing systems for aggregates and cementing agents, water dosing via flowmeter or weight, and automated control software to ensure precision and traceability.

Perfect for producing base layers and/or base stabilization soils, mixed concrete, compacted concrete (HCR, CCR), soil-cement mixtures, and backfill materials in the mining sector.

DMB series specifications

Production (Lb/h): | (98,0~104,6) |

Mixer capacity per batch (Yd3): | (3.923/2.615) |

Mixer Type: | Continued double axis |

RMP Mixing shafts: | 25 |

Mixing paddles: | 12+2+12 |

Floor, wall and pallet coverings: | Replacement |

Type of motor: | Three-phase electric |

Engine power (Hp): | 2*50 |

Number of hoppers for aggregates: | 2~4 |

Aggregate hopper capacity (Yd3): | 19,6 |

Control and dossing software: | D-200 |

Production (Lb/h): | (124,2~130,7) |

Mixer capacity per batch (Yd3): | (4.904/3.269) |

Mixer Type: | Continued double axis |

RMP Mixing shafts: | 25 |

Mixing paddles: | 16+2+2 |

Floor, wall and pallet coverings: | Replacement |

Type of motor: | Three-phase electric |

Engine power (Hp): | 2*60 |

Number of hoppers for aggregates: | 2~4 |

Aggregate hopper capacity (Yd3): | 19,6 |

Control and dossing software: | D-200 |

Production (Lb/h): | (130,7~156,9) |

Mixer capacity per batch (Yd3): | (5.885/3.923) |

Mixer Type: | Double horizontal axis |

RMP Mixing shafts: | 25 |

Mixing paddles: | 16+2+2 |

Floor, wall and pallet coverings: | Replacement |

Type of motor: | Three-phase electric |

Engine power (Hp): | 2*75 |

Number of hoppers for aggregates: | 2~4 |

Aggregate hopper capacity (Yd3): | 19,6 |

Control and dossing software: | D-200 |

Production (Lb/h): | (98,0~104,6) |

Mixer capacity per batch (Yd3): | (3.923/2.615) |

Mixer Type: | Double horizontal axis |

RMP Mixing shafts: | 25 |

Mixing paddles: | 12+2+2 |

Floor, wall and pallet coverings: | Replacement |

Type of motor: | Three-phase electric |

Engine power (Hp): | 2*50 |

Number of hoppers for aggregates: | 2~4 |

Aggregate hopper capacity (Yd3): | 19,6 |

Control and dosing software: | D-200 |

|

Production (Lb/h): |

(124,2~130,7) |

|

Mixer capacity per batch (Yd3): |

(4.904/3.269) |

|

Mixer Type: |

Double horizontal axis |

|

RMP Mixing shafts: |

25 |

|

Mixing paddles: |

16+2+2 |

|

Floor, wall and pallet coverings: |

Replacement |

|

Type of motor: |

Three-phase electric |

|

Engine power (Hp): |

2*60 |

|

Number of hoppers for aggregates: |

2~4 |

|

Aggregate hopper capacity (Yd3): |

19,6 |

|

Control and dosing software: |

D-200 |

|

Production (Lb/h): |

(130,7~156,9) |

|

Mixer capacity per batch (Yd3): |

(5.885/3.923) |

|

Mixer Type: |

Double horizontal axis |

|

RMP Mixing shafts: |

25 |

|

Mixing paddles: |

16+2+2 |

|

Floor, wall and pallet coverings: |

Replacement |

|

Type of motor: |

Three-phase electric |

|

Engine power (Hp): |

2*75 |

|

Number of hoppers for aggregates: |

2~4 |

|

Aggregate hopper capacity (Yd3): |

19,6 |

|

Control and dossing software: |

D-200 |